Robotized Drilling and Workover Rig

Our patented Rigtec technology simplifes and modernizes oil recovery operations across land rigs, jack-ups, and semisubmersibles. Delivered by RoboRig™: the robotized workover- and drilling rig.

Decreased

CAPEX / OPEX

Modular

and Purpose Built

Reduced

Carbon Footprint

Enhanced

Safety

Areas of Use

Rigtec operates using our RoboRig™ technology for versatile deployment across both onshore and offshore drilling and workover operations.

Whether on land rigs, jack-ups, or semisubmersibles, RoboRig™ offers a faster, lighter, and more cost-effective alternative to today’s conventional drilling and intervention.

For information about the subsea well intervention applications of RoboRig™: Rigtec Wellservice.

Rigtec RoboRig™ areas of use showcase video. (1) onshore drlling rig, (2 and 3) jack-up/semi/platform, (4) continuous tripping movement.

ONSHORE

Drilling Rig

Workover Rig

-

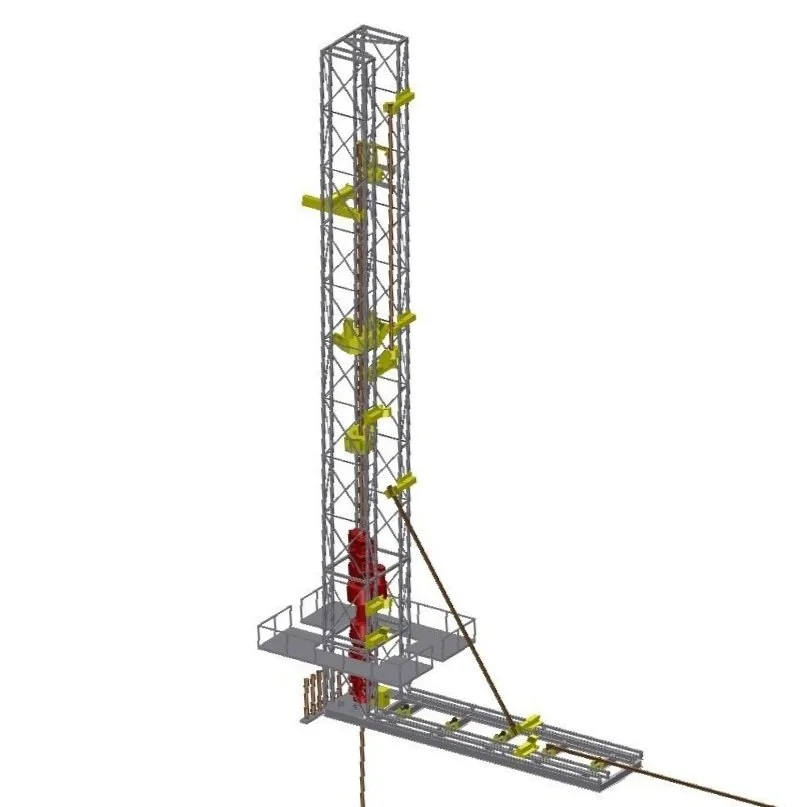

Compact, High-Output Modular Design

Lightweight yet industrial-strength, Roborig’s modular architecture replaces bulk with agility—ideal for tight sites and high-mobility deployments.Unmatched Tripping Speeds (up to 1,800 m/h)

Robotic drive systems enable 0.5–0.75 m/s equipment movement, cutting well intervention time dramatically.No Vertical Pipe Rack Required

Innovative handling eliminates the need for vertical racking, reducing rig height, complexity, and footprint.Full Robotic Automation

Executes entire drilling and workover sequences without human input—repeatable, precise, and programmable for all operations.Universal String Compatibility

Seamlessly handles all casing, tubing, and specialized strings—supporting a wide range of well designs and intervention scopes.

-

Significant Reduction in Drilling & Intervention Costs

Outperforms optimised traditional rigs through time savings, automation, and reduced personnel requirements.Optimised for Pad Drilling & Multi-Well Strategies

High-density pad applications benefit from Roborig’s compact profile and continuous performance, enhancing ROI per location.Rapid Deployment & Redeployment

Modular system reduces rig-up/rig-down times and simplifies logistics, unlocking faster field-to-field mobility.Lower Fabrication & Lifecycle Costs

Smart materials, streamlined components, and fewer mechanical failure points translate into significantly reduced CAPEX and maintenance spend.

-

Less Diesel Consumption

The hybrid diesel-electric system dramatically reduces emissions and fuel dependency, future-proofed with grid and renewable integration.200–300 kW Power Consumption

Less than half the energy draw of traditional rigs, enabling operations in power-constrained or off-grid environments.Minimal Surface Footprint

Ideal for environmentally sensitive areas—reduces pad size, earthworks, and ecological impact.Regenerative Braking & Energy Capture

Captures kinetic energy during down cycles to power torque-intensive processes, boosting efficiency and lowering net consumption.

OFFSHORE

Semi/Platform

Jack-up

-

Zero Drill Pipe Racking Required: No need to rack stands or singles—streamlines handling and eliminates vertical pipe storage risks.

Horizontal Pipe Delivery: Single drill pipe sections are fed horizontally, drastically reducing manual handling and mechanical strain.

Quadruple Derrick Design: Lightweight, low-profile derrick system—significantly smaller in size and weight compared to conventional rigs.

Movable Rotary Table: Allows flexible positioning of the drilling axis, enabling multi-well pad-style operations from a single jack-up deployment.

Enhanced Safety Layout: Increases physical distance between personnel and rotating or suspended equipment—minimising risk exposure.

Modular Compact Structure: Low-weight components and reduced height profile allow for simplified installation, maintenance, and logistics.

Full Operational Accessibility: Each rig unit remains accessible and functional throughout the drilling process, ensuring high availability and task readiness. Cantilever extension greater

Seamless transition between operations: As one rig unit performs its tasks (e.g., drilling), the other rig units are prepared for subsequent activities. This parallel operation optimises resource use and minimises downtime

-

Faster Drilling Cycles: Automated handling and efficient design lead to reduced tripping and connection time, cutting total drilling days.

Smaller Footprint, Smaller Costs: Lower derrick weight and height reduce platform demands, logistics complexity, and support vessel requirements.

Reduced Mobilisation & Installation Time: Plug-and-play rig modules allow for rapid deployment on jack-up rigs with minimal retrofitting.

Electrified System Reduces Fuel Costs: Fully electric operation slashes fuel usage, eliminates diesel generator dependency, and reduces long-term OPEX.

Minimised Crew & Maintenance Requirements

Automation and compactness translate to lower labour, inspection, and repair overhead.

-

Low Emissions with Full Electrification: Replaces diesel-driven systems, cutting both direct and indirect emissions at the source.

Minimised Surface Impact: Smaller design and simplified logistics reduce the environmental burden during transport, setup, and operations.

Idle Time Reduction: Efficient workflows and automatic transitions between drilling phases reduce equipment downtime and environmental footprint.

Green-Compatible Jack-Up Integration: Fits into existing electrification strategies for offshore assets, supporting long-term sustainability goals.

Contact Rigtec

Do you wish to know more about Rigtec?

Please feel free to use our contact form or contact Tor Egil Rolfsen directly.

Do you wish to know more about Captec?

Send an email to contact@captec.no, or call

+47 901 47 798